Problem Description

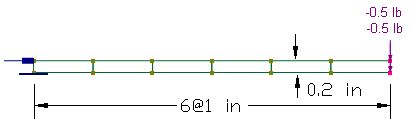

A 6 x 0.2 inch cantilever plate is loaded with two separate sets of loads [Ref. 4, pp3-20].

a). An in-plane shear of 1 lb at the tip.

b). An axial load of 1 lb at the tip.

Material: E = 1.0e7 psi; ν = 0.3

Thicknesses: t = 0.1 inch.

Determine the tip displacements in the directions of applied loads, using a 6 x 1 mesh as suggested by the reference.

Suggested Modeling Steps

▪Set proper units from Settings and Tools > Units & Precisions.

▪Generate the first plate by Create > Templates > Rectangular Shells. Enter a distance list of “6@1” for the X direction and a distance list of “0.2” for the Y direction.

▪Select all shell elements, define and assign material properties by Modify > Shell Properties > Materials. Make sure “Assign active material to currently selected elements” is checked in the dialog box.

▪Select all shell elements, define and assign the shell thickness properties by Modify > Shell Properties > Thicknesses. Make sure “Assign active thickness to currently selected shells” is checked in the dialog box.

▪Press ESC key to unselect all. Select the bottom-left node and assign it a fixed support. Select the top-left node and assign it a support restrained in Dx.

▪Define two load cases named “InPlaneShear” and “Axial”.

▪Define two load combinations. In the first load combination, set the load factor of 1.0 for load case “InPlaneShear” and 0s for other load cases. In the second load combination, set the load factor of 1.0 for load case “Axial” and 0s for other load cases.

▪Select two nodes at the tip, assign each node a 0.5 lb, Y-direction nodal loads of load case “InPlaneShear” by Create > Draw Loads > Nodal Loads. Select two nodes at the tip, assign each node a 0.5 lb, X-direction nodal loads of load case “Axial” by Create > Draw Loads > Nodal Loads.

▪Set the analysis options by Analysis > Analysis Options. Choose the model type “2D Plane Stress”. Check or uncheck “Use incompatible formulation for shell membrane actions or bricks”.

Results

The comparison of the displacements (inches) in the directions of loads between the program and the referenced results is mixed.

|

Membrane formulation |

ENERCALC 3D |

[Ref. 4] |

Case a) |

Compatible |

-0.0101 |

0.1081 |

Incompatible |

-0.1073 |

0.1081 |

|

Case b) |

Compatible or Incompatible |

3.0e-5 |

3.0e-5 |

Comments

The example problem tests the in-plane (membrane) component of the shell element. Two separate analyses are performed for case a) and case b). The incompatible membrane formulation models in-plane bending very well. The compatible membrane formulation is too stiff to model in-plane bending when a coarse mesh is used. However, both formulations work well when fine element meshes are used.