When performing a finite element analysis with quad shells, there are some geometric guidelines to keep in mind for the individual shells in order to ensure quality results.

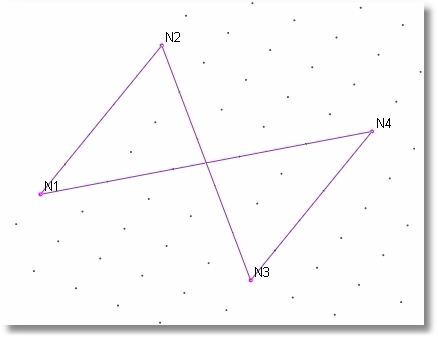

Order of Node Selection: We have already seen that it is important to define shells in either a clockwise or counter-clockwise order to avoid warped plates which will produce invalid results.

NOT GOOD!

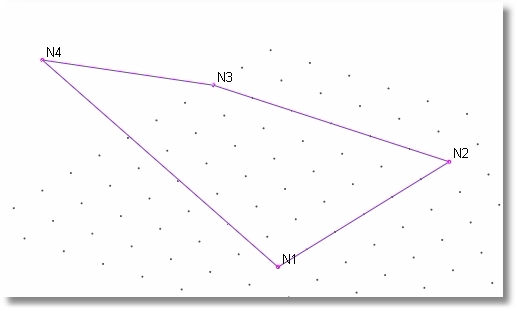

Planar Geometry: Along similar lines, it is important to ensure that all four nodes of a quad shell lie in one plane.

NOT GOOD!

Shape: The ideal shape for a quad shell is a square. The more a quad shell deviates from a square, the greater the chances of introducing some error into the results. But in practical situations, it is not always possible to keep shells square, so here are some additional considerations to keep in mind with regard to shell quality:

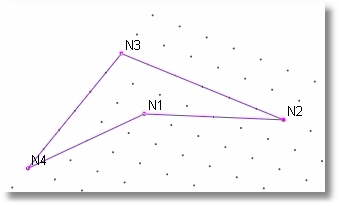

Angles: Shells have some ability to tolerate angles other than 90 degrees, but try to avoid extreme skews. Interior angles should range between 60 and 120 degrees. Never create a shell that has an included angle that exceeds 180 degrees.

NOT GOOD!

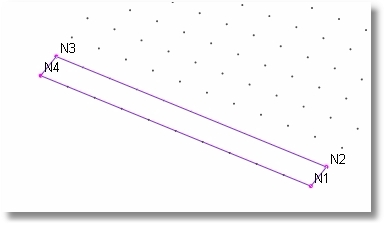

Aspect Ratio: Shells have some ability to become rectangular, but try to avoid extreme aspect ratios. It is good to try to keep aspect ratios less than 2:1. Never create a quad shell with an aspect ratio that exceeds 4:1.

NOT GOOD!

Note that when it comes to improving shell quality, the solution is often to just break a poorly shaped shell into more shells that all have better quality.

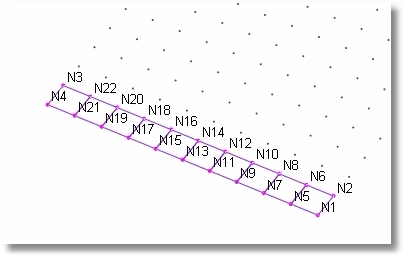

MUCH BETTER!

This is a good segue into the next topic, which is mesh density.

Size Variation: We will cover the topic of mesh density in great detail in the section titled Mesh Density. But for the purposes of the discussion on shell quality, let it suffice to say that it is good practice to try to make the elements of a given mesh generally about the same size.