Objective

To verify compatible and incompatible membrane formulations

Problem Description

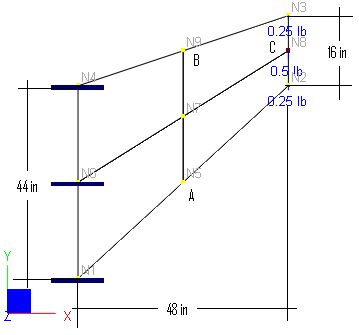

The skewed cantilever plate shown below is subjected to a distributed shear of 1 lb at the end.

Material properties: E = 1.0 psi, ν = 0.333

Thickness t = 1 in

Finite Element Model

4 shell elements

Model type: 2D Plane Stress (using compatible and incompatible formulations)

Results

The best results are given by [Ref 1] as follows:

Displacement Dy @ C: 23.9 in

Principal stress S1 @ A: 0.236 psi

Principal stress S2 @ B: -0.201 psi

Units: displacement – in; stress - psi

|

Compatible formulation |

Incompatible formulation |

||||

|

Displacement Dy @ C |

Principal Stress S1 @ A |

Principal Stress S2 @ B |

Displacement Dy @ C |

Principal Stress S1 @ A |

Principal Stress S2 @ B |

2 x 2 mesh |

11.85 |

0.1078 |

-0.07762 |

21.05 |

0.1789 |

-0.1694 |

64x64 |

23.92 |

0.2376 |

-0.2038 |

23.96 |

0.2368 |

-0.2035 |

[Ref 1] |

23.9 |

0.236 |

-0.201 |

23.9 |

0.236 |

-0.201 |

Comments

The results given by ENERCALC 3D are compared with the referenced values. For the 2 x 2 coarse mesh, the incompatible formulation is superior to the compatible one. For the 64 x 64 fine mesh, both compatible and incompatible formulations give satisfactory results.

Reference

[1]. Bergan & Filippa, “Triangular membrane element with rotational degrees of freedom”, Comput. Meth. Appl. Mech. Engng., 50: 25-69, 1985