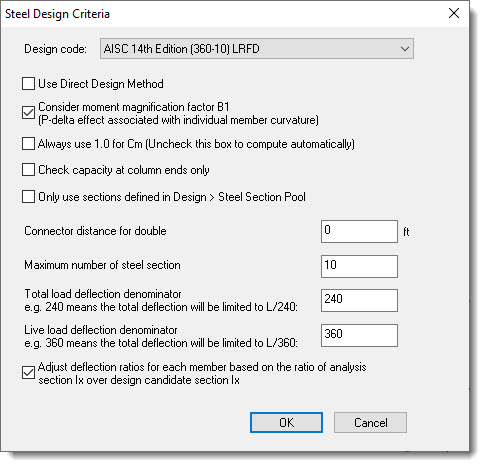

Click Steel Design > Steel Design Criteria > Steel Design Criteria to open the Steel Design Criteria dialog. This dialog controls many aspects of the steel design process.

Design Code: Select the desired code.

Use Direct Design Method: Selecting this option affects the calculation of moment magnification factor B1 See AISC Eq. (A-8-3), Eq. (A-8-5), Eq. (C2-2a) and Eq. (C2-2b). It does not create notional loads.

Consider moment magnification factor B1: B1 is moment magnification factor for small p-delta along the member length. With this flag on, you do not need to break a member into multiple members in order to consider small p-delta effect.

Always use 1.0 for Cm: Forces Cm = 1 as opposed to using equation (A-8-4).

Check capacity at column ends only: If this is not selected, the steel design procedure will check columns at every analysis segmental point along the member (more calculation time).

Only use sections from the Section Pool: If this is not selected, the steel design procedure will not limit itself to sections in the Section Pool. Instead, it will stay within the family specified by the Section Prefix specified in Member Design Criteria.

Connector distance for double-angle members: Distance between intermediate connectors in double-angle members for use in Eq. (E6-2b).

Maximum number of steel sections to solve for: Tells the steel design routine how many passing sections to search for.

Total load deflection denominator: Total load deflection will be limited to span length/Total load deflection denominator.

Live load deflection denominator: Live load deflection will be limited to span length/Live load deflection denominator.

Adjust deflection ratios...: This item should be checked to prevent the situation where no candidate section is available when critical ratio in design for a member is caused by deflection limits.