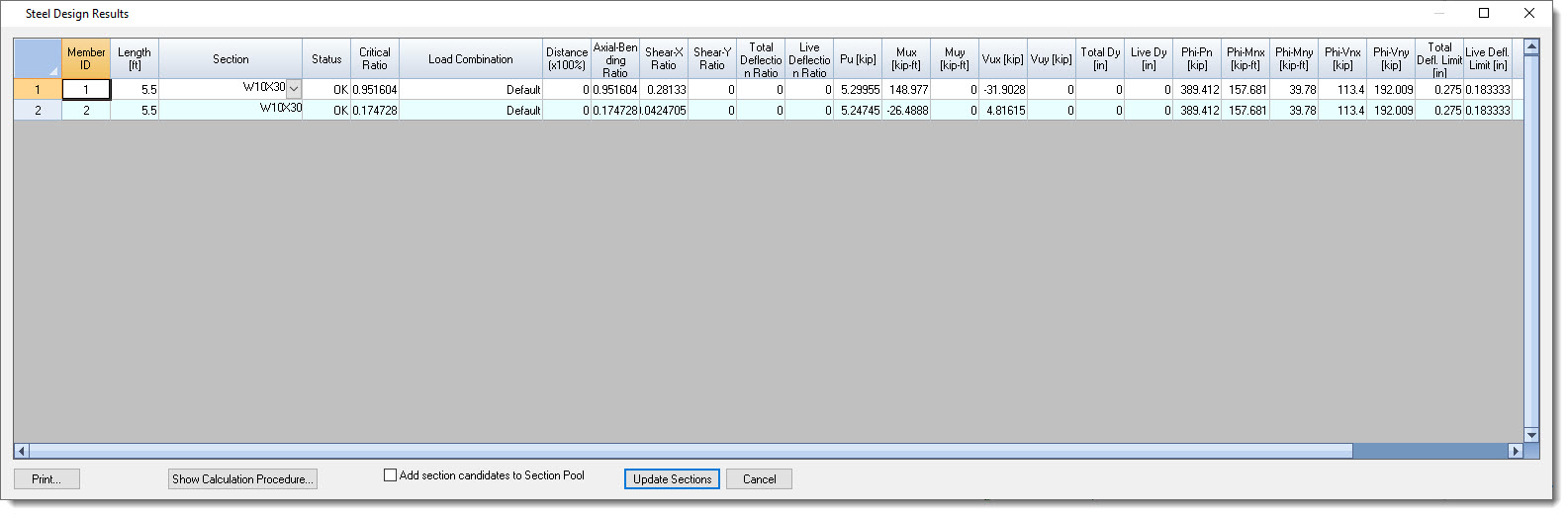

Click Steel Design > Steel Design Results to open the Steel Design Results table.

This table presents the results of the most recent Steel Design process. Each line represents a member in the model and presents the following data:

Member ID: The ID of the member.

Length: The actual member length, not the unbraced length for flexure or for Euler buckling.

Section: The AISC section for which design results are displayed.

Tip: Click the dropdown arrow in the Section cell to view a list of other sections selected by the Steel Design routine subject to the limitations of the Section Prefix and the Section Pool.

Tip: Selecting a different section will invalidate the analysis results due to changes in stiffness. So be sure to reanalyze the model and rerun the Steel Design after making any section changes.

Status: Indicates an OK or NG status to show whether the selected member satisfies code requirements or not.

Critical Ratio: Reports the highest ratio found after running all of the required steel code checks on the member considering Axial & Bending, Shear, and Deflection.

Load Combination: Indicates the Load Combination responsible for producing the Critical Ratio.

Distance: Reports the location where the critical design was found to occur. 0 indicates that the critical design location was at the starting end of the member. 1 indicates that the critical design location was at the ending end of the member. A decimal indicates a location somewhere in between starting and ending end.

Axial-Bending Ratio: Indicates the highest ratio that occurred on the member due to combined axial and flexural design when subjected to the load combination that produced the Critical Ratio.

Shear-X Ratio: Indicates the highest ratio that occurred on the member due to strong direction shear when subjected to the load combination that produced the Critical Ratio.

Shear-Y Ratio: Indicates the highest ratio that occurred on the member due to weak direction shear when subjected to the load combination that produced the Critical Ratio.

Total Deflection Ratio: Calculated as controlling Total Load Deflection/(Span/Total Load Deflection Denominator) when subjected to the load combination that produced the Critical Ratio.

Live Deflection Ratio: Calculated as controlling Live Load Deflection/(Span/Live Load Deflection Denominator) when subjected to the load combination that produced the Critical Ratio.

Pu: Axial load at the controlling distance when subjected to the load combination that produced the Critical Ratio.

Mux: Moment about the strong axis at the controlling distance when subjected to the load combination that produced the Critical Ratio.

Muy: Moment about the weak axis at the controlling distance when subjected to the load combination that produced the Critical Ratio.

Vux: Shear in the strong direction at the controlling distance when subjected to the load combination that produced the Critical Ratio.

Vuy: Shear in the weak direction at the controlling distance when subjected to the load combination that produced the Critical Ratio.

Total Dy: Total Load strong axis deflection.

Live Dy: Live Load strong axis deflection.

PhiPn: Axial capacity.

PhiMnx: Strong axis moment capacity.

PhiMny: Weak axis moment capacity.

PhiVnx: Strong direction shear capacity.

PhiVny: Weak direction shear capacity.

Total Deflection Limit: Span/Total Load Deflection Denominator.

Live Deflection Limit: Span/Live Load Deflection Denominator.

Cb: Lateral-torsional buckling modification factor for nonuniform moment diagrams.

Cmx: Coefficient accounting for nonuniform moment about the strong axis.

Cmy: Coefficient accounting for nonuniform moment about the weak axis.